zProduction

Sandeza S.r.l

Summary

Product Type: Apps

Price: Starting at € 2.000

Last updated: 5/6/2019

Language: English

Product websiteCategory

Process Management Platform

zProduction is designed and realized to simplify and integrate daily production work.

zProduction is a modular and integrated software, each module can be used individually, but they all share the same databases. The system contains an entire section dedicated to the production from every point of view: from the management and the creation of the products to the planning the production itself.

The system can archive and manage every product, component and spare part, classifying them by product categories, allowing the input of different set of technical information for every product, inserting the bill of material and creating and managing the maintenance plan. The history of interventions, issues and solutions on the products is available.

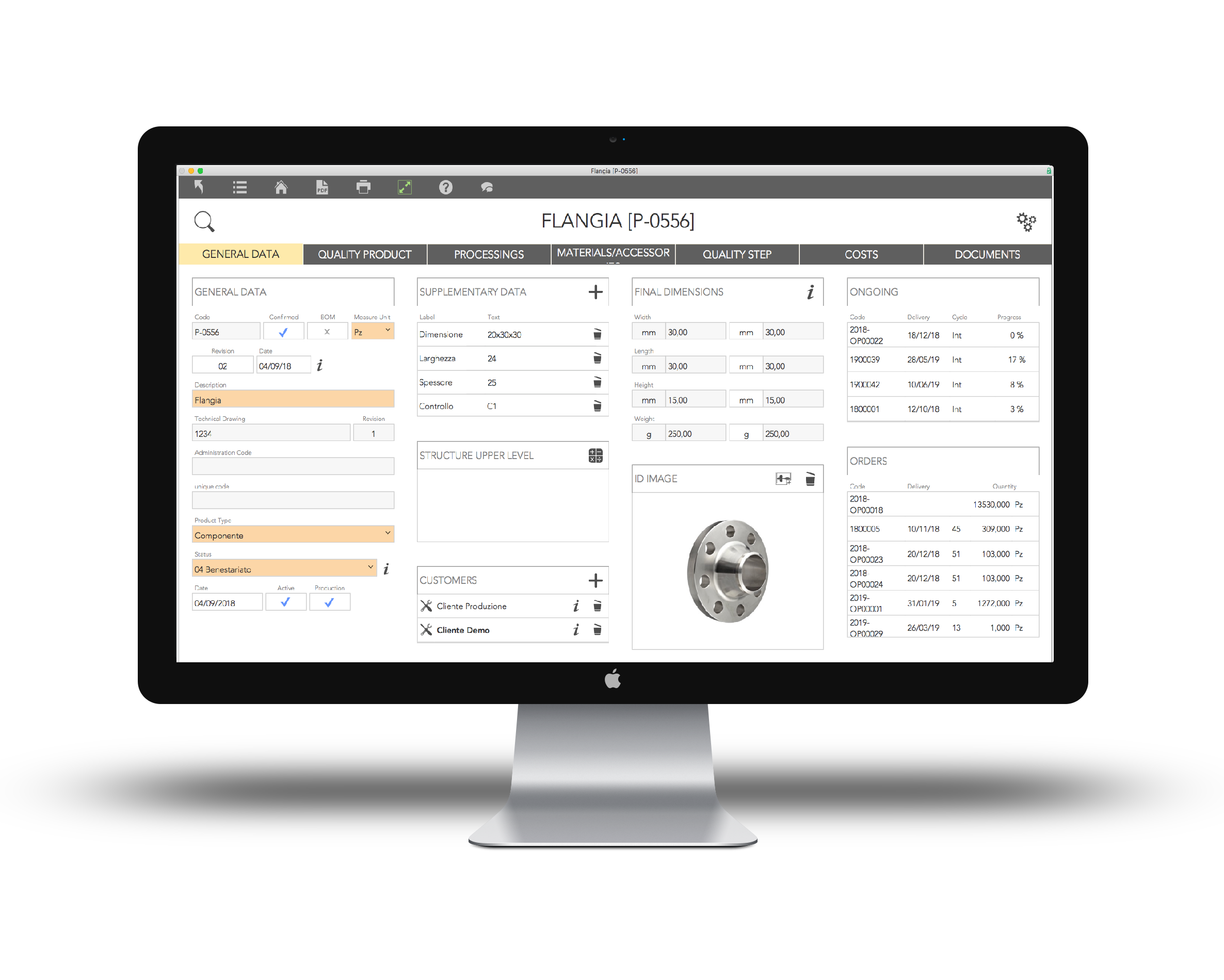

The product page is at the core, where the technical specs of the production process, quality control plan, costing, documents, pictures and multimedia files regarding the workflow are stored.

Other information regarding the buy and sell process can be stored, such as default suppliers, specific customer and suppliers product identifiers, prices, minimum stock and warehouse position. The archive is structured in a way that allows to track the different product identifiers, the status, the picture and the size of the product.

A tools archive is also available and it allows to store information related to the tools such as the structure of a tool, the status of usage, where they are used along the different production processes and also the purchasing price list.

Information are shared along the system to help managing the stock: input and output, booking and stock fixings. Every stock movement is tracked down and they all make up the historical of the stock movements.

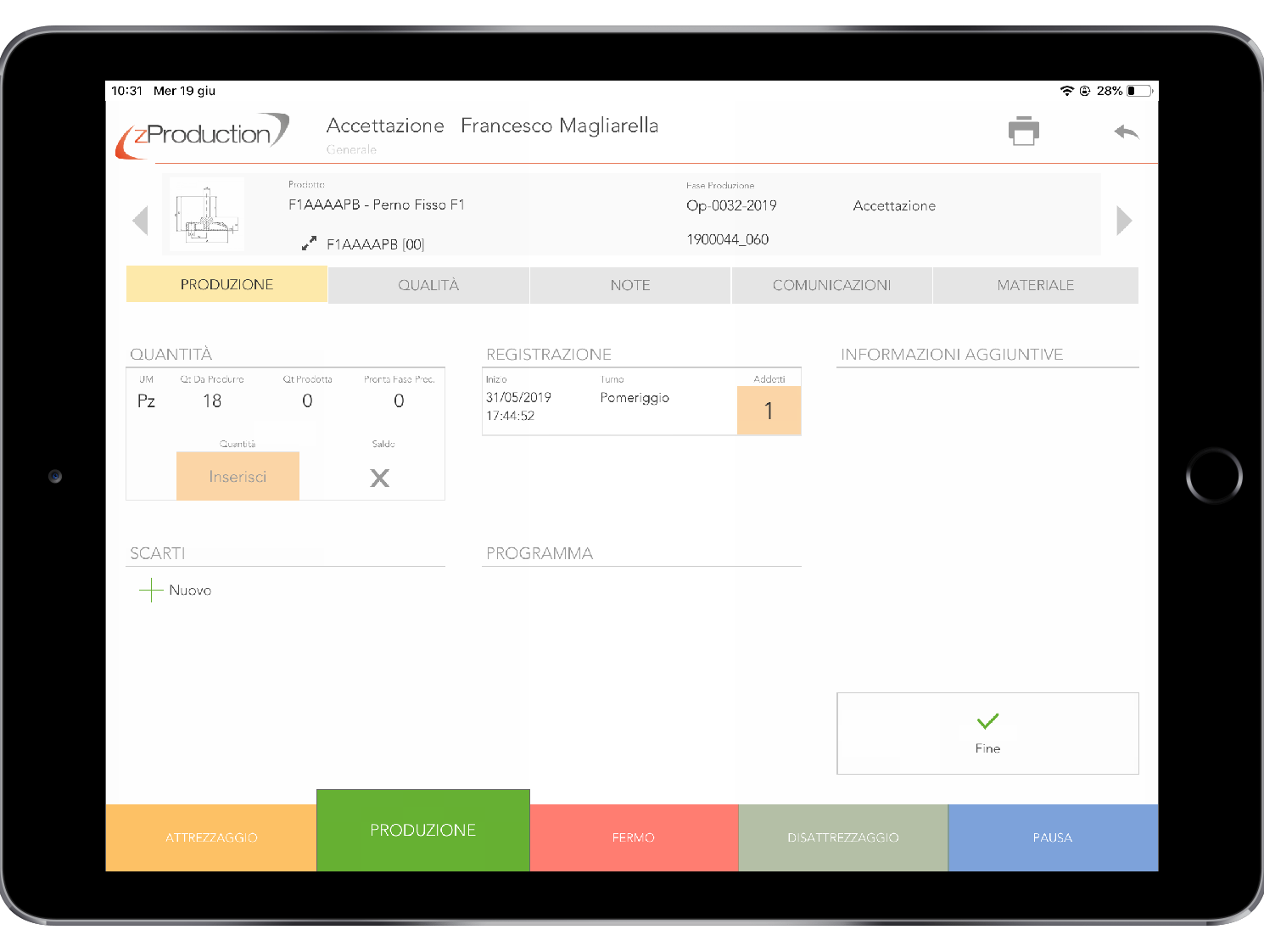

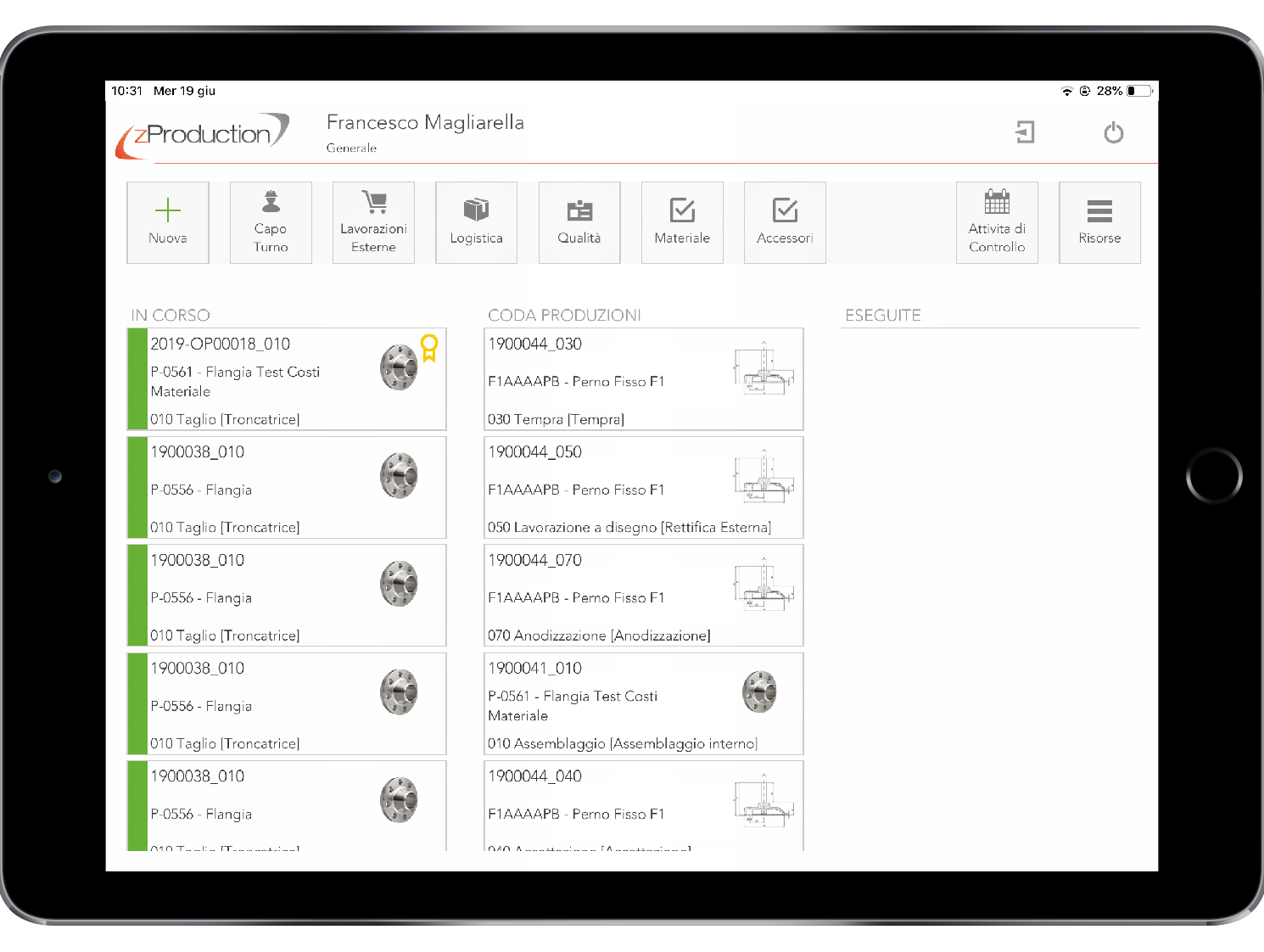

Operators will use mobile devices to track the production and easy access and collect quantity and quality data during the process.

Data collection speeds up the control of the process avoiding paperworks and all the errors related to it.

zProduction allows you to plan the production machines’ activities automatically, taking into account the schedules and the orders’ priority. Operators can see the production list and directly collect all the relevant production data. Data collection speeds up quality controls, eliminates the need for paper trails and always works with live data, keeping all the involved parties updated.